Which Technologies Can Help Improve Efficiency in a Stoke-on-Trent Manufacturing Business?

As the heart of the West Midlands, Stoke-on-Trent is a dynamic hub of industry and commerce. Factories and businesses in the region have always been at the forefront of growth and innovation. Incorporating advanced technologies into the manufacturing industry is a strategic move that can put businesses a step ahead in this fast-paced digital era. In this article, we'll explore the technologies that can push your manufacturing business towards smarter productivity.

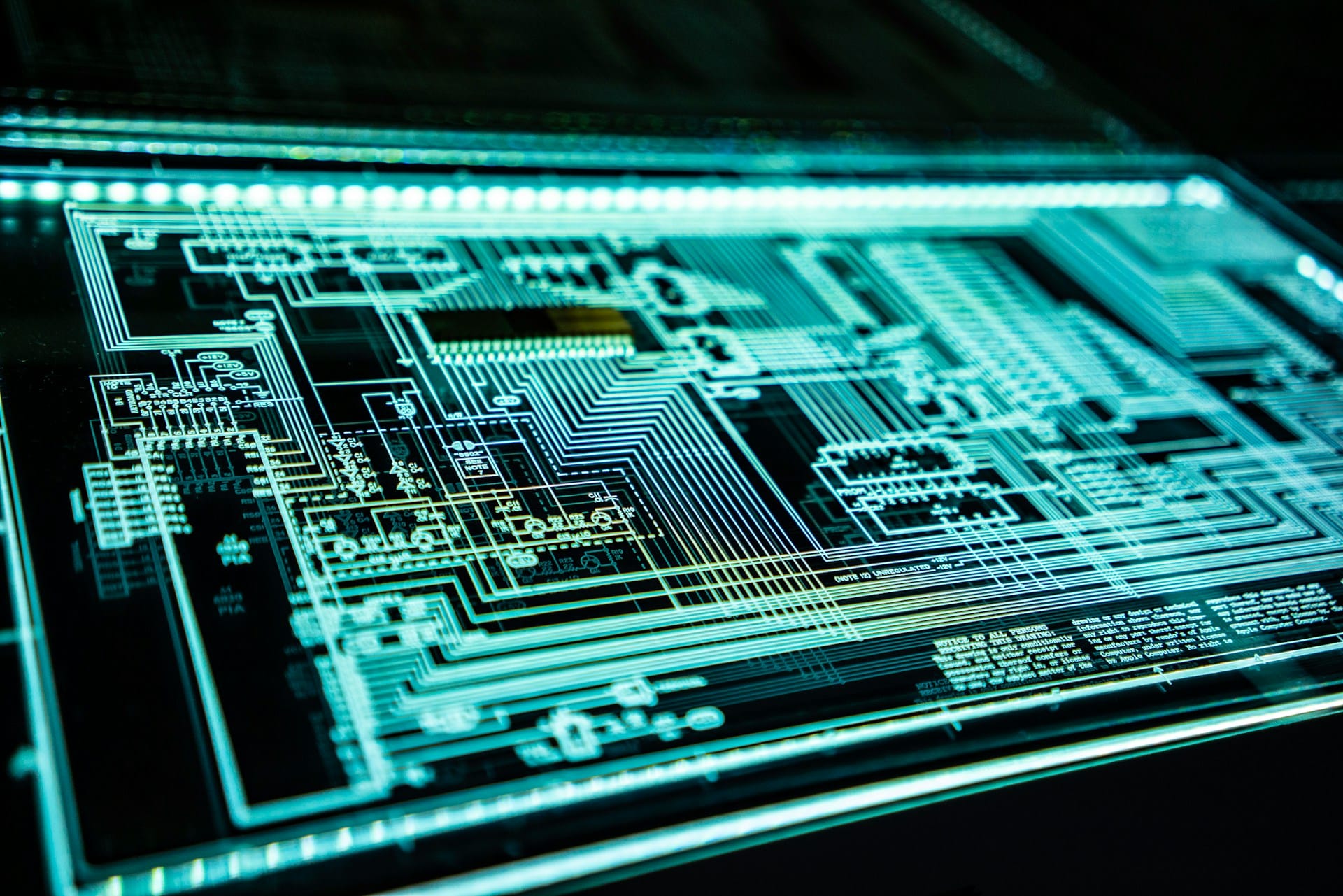

Embracing Digital Transformation

The digital revolution is not just reshaping the business landscape but is also re-engineering the manufacturing industry. From data analytics to smart machinery, digital technology is opening up new avenues for businesses to increase efficiency and productivity.

Also to read : Obtenez votre permis de conduire en ligne à tarare facilement

The ability to access, analyse and utilise data can be a game-changer for manufacturing businesses. Data allows you to understand your business better, predict trends, and make data-driven decisions. Software solutions like Enterprise Resource Planning (ERP) and Manufacturing Execution Systems (MES) enable businesses to streamline their operations and improve productivity.

There's no doubt that Coventry has been a significant player in the adoption of digital technology in the manufacturing sector. The Coventry and Warwickshire Business Support Programme provide funding and support for businesses to take advantage of digital technology. This programme has been a catalyst for businesses in Staffordshire, Coventry and across the West Midlands to embrace digital transformation.

Also read : How Can Ipswich Coffee Shops Leverage Local SEO to Increase Foot Traffic?

Smart Manufacturing and IoT

Smart manufacturing is another technology that has the potential to transform manufacturing businesses. It integrates physical machinery with networked sensors and software, using data and predictive analytics to optimise the manufacturing process. This is where the Internet of Things (IoT) comes into play.

IoT devices connect to the internet and communicate with each other. In the manufacturing sector, IoT devices can monitor and collect data from multiple points in the manufacturing process. This data can be analysed to predict and prevent equipment failures, reduce downtime, and increase efficiency.

Staffordshire and West Midlands businesses have made significant strides in implementing smart manufacturing practices. It's a trend that Stoke-on-Trent businesses should seriously consider. The benefits of smart manufacturing and IoT are immense and can propel your business to new heights of productivity and growth.

Cloud Technology

As we look to the digital horizon, we can see that cloud technology has become a staple for businesses across all sectors, including manufacturing. The cloud refers to software and services that run on the internet instead of your computer. Businesses can use cloud-based software to access and store data, manage customer relations, automate tasks, and much more.

By migrating to the cloud, you can reduce the cost and complexity of owning and operating computers and networks. You can also scale up or down as your needs change, giving your business the flexibility it needs to grow.

In the West Midlands region, manufacturers have been increasingly adopting cloud technology. It's a smart move that can help you streamline your operations and make your business more efficient and productive.

Artificial Intelligence (AI)

AI is another technological advancement that has made a significant impact on the manufacturing industry. AI can automate routine tasks, analyse large volumes of data, and predict outcomes. This can lead to increased efficiency and productivity.

In manufacturing, AI can be used in areas such as quality control, predictive maintenance, demand forecasting, and supply chain optimisation. By leveraging AI, manufacturers can improve their decision-making process, reduce errors, and increase their productivity.

The West Midlands, and particularly Staffordshire, is at the forefront of AI adoption in the manufacturing sector. Businesses in the region are harnessing the power of AI to drive growth and improve efficiency.

Advanced Robotics

In modern manufacturing, the use of advanced robotics is becoming increasingly prevalent. These sophisticated machines can perform tasks with a level of precision and efficiency that surpasses human capabilities.

Robotic technology enables manufacturers to automate repetitive tasks, improve product quality, and reduce waste. It also boosts productivity by allowing for round-the-clock production.

Stoke-on-Trent manufacturers should consider investing in advanced robotics as part of their growth strategy. With the region's strong engineering heritage, the adoption of robotics presents a significant opportunity to further enhance productivity in the West Midlands.

From data analytics to advanced robotics, these technologies offer exciting possibilities for Stoke-on-Trent manufacturers. By embracing these trends, businesses in the region can drive smarter growth and productivity in this digital era.

Virtual Reality (VR) and Augmented Reality (AR)

In a vibrant, industrious region like the West Midlands, incorporating technologies such as Virtual Reality (VR) and Augmented Reality (AR) can be vital in achieving smarter productivity for manufacturing businesses. These technologies, often seen as the new frontiers of the digital revolution, offer an immersive, interactive experience that can significantly improve efficiency in the manufacturing sector.

VR provides a fully simulated environment, which can be used in manufacturing engineering for design and testing purposes before the actual product is produced. This not only reduces waste but also enhances the quality of the final product. With VR, Stoke-on-Trent businesses can conduct virtual trials of complex manufacturing processes, reducing both time and cost.

On the other hand, AR overlays digital information onto the real-world view of the user. This can be extremely beneficial for manufacturing businesses in staff training and maintenance. AR can provide real-time data and visual guidance, thereby improving accuracy and efficiency. For instance, in the context of supply chain management, AR can assist in tracking and managing inventory, ensuring operational efficiency.

The Coventry and Warwickshire Business Support Programme, and the West Midlands Combined Authority, are providing considerable support for businesses to integrate VR and AR technologies. The Smarter Programme at the University of Warwick also promotes the application of these advanced manufacturing techniques. Stoke-on-Trent Staffordshire firms should seize these opportunities to drive their growth in the digital age.

3D Printing

3D printing, also known as additive manufacturing, is a technology that has the potential to revolutionise the manufacturing industry in Stoke-on-Trent. It enables manufacturers to create three-dimensional objects from a digital file, layer by layer. This technology can lead to substantial cost savings, improved product quality, and a reduction in lead times.

With 3D printing, businesses can create prototypes quickly and cheaply, enabling them to test and refine products before they go to market. This results in a faster and more efficient product development cycle. Moreover, 3D printing allows for the production of complex and customised parts in a single process, reducing the need for multiple manufacturing steps and tools.

The West Midlands Growth Hubs are promoting the adoption of 3D printing technology in the region's manufacturing businesses. The Black Country Business News has highlighted several success stories of firms that have benefited from 3D printing. It is a trend that Stoke-on-Trent businesses should follow to stay ahead in the competitive market.

Conclusion

In today's digital era, Stoke-on-Trent manufacturing businesses can no longer afford to ignore the technological advancements that have the potential to drive their growth and efficiency. From data analytics to AI, and from VR and AR to 3D printing, these digital technologies offer immense benefits.

The West Midlands, with its strong engineering heritage and supportive business programs like the Coventry and Warwickshire Business Support Programme, the Smarter West programme at the University of Warwick, and the Midlands Combined Authority, offers a conducive environment for businesses to embrace digital transformation.

As we look to the future, it is clear that the integration of these technologies will be a key determinant of success in the manufacturing industry. Stoke-on-Trent firms should seize this opportunity to leverage the power of digital technology, ensuring smarter growth and productivity in this rapidly evolving landscape.